5 Common Reasons Why Your Perfume Bottle Pump Broken

Table of Contents

Perfume Bottle Pump may have various problems which plague perfume sprayer users.

This blog explains in detail the 5 Common Reasons of Perfume Bottle Pump Broken.Apart from this, it also provides a cross-reference table for checking perfume bottle pump broken and ways to prevent it.

what is a perfume bottle pump?

The Perfume Bottle Pump is a spraying device mounted on the mouth of a perfume bottle. Its function is to spray the liquid perfume inside the bottle by pressing and atomizing it evenly for the user to easily apply the perfume on the body or clothing.

The perfume bottle pump is an indispensable component of perfume packaging. It makes perfume easier to use, more elegant and more branded, and is the “key to the release of the fragrance”.

5 Common Reasons of Perfume Bottle Pump Broken

Damage” to perfume pumps is commonly caused by structural fatigue, clogging, improper assembly, or improper use. By observing the elasticity of the pump head, the state of the nozzle, and the fit between the pump and the mouth of the bottle, you can quickly determine whether it is a structural failure or a functional jam, and then decide whether it needs to be replaced or repaired.

1️⃣ Pump head is loose or won't return (spring failure)

Detailed Explanation:

Perfume pumps rely on a miniature metal spring inside the pump to help the pump core spring back quickly after being pressed. If this spring fails or breaks due to metal fatigue, corrosion, over-pressurization, or improper factory assembly, the pump head will become “floppy” – it won’t spring back after being pressed, and it won’t squirt liquid.

Specific performance:

- Press down easily, but no rebound;

- Can not spray perfume, even if there is liquid;

- There is a “pump trapped in the stuck” feeling.

2️⃣ No response to pressing, no mist at all

Detailed explanation:

If there is perfume residue in the pump core passage or the suction tube is not connected correctly (too short, detached, skewed), the liquid cannot be drawn into the pump core at all. Especially when used for the first time, the lack of “pre-pressure start” can also lead to misjudgment of the pump as bad.

Performance:

- There is an “airy feeling” when pressing;

- No liquid output, but the nozzle is structurally intact;

- The bottle may occasionally spray once or twice after being turned upside down or shaken.

3️⃣ Nozzle is crooked, clogged or leaking fluid

Detailed explanation:

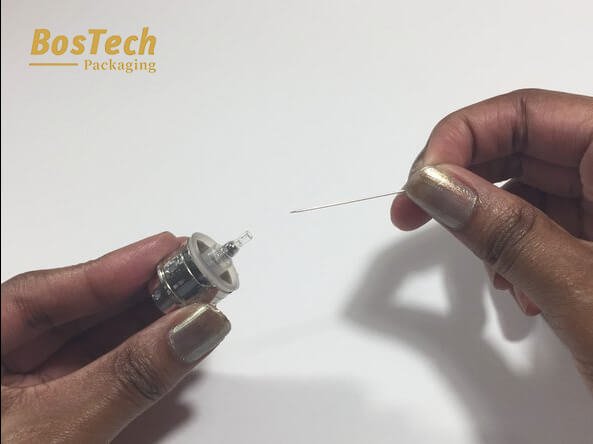

The diameter of the nozzle of a perfume pump is very tiny (usually about 0.2~0.4mm). If the perfume contains oily ingredients, botanical extracts, glitter or sediments, the nozzle will be partially clogged after long-term use. In addition, if the nozzle cap is deformed or squeezed, it will also lead to crooked spray or leakage.

Performance:

- Spraying diagonal lines and water droplets instead of fine atomization;

- White crystals accumulate around the nozzle;

- Traces of perfume oozing from the edge of the bottle after use.

4️⃣ Broken or outright dislodged pump head (mechanical breakage)

Detailed explanation:

This is the most intuitive damage, generally appear in the perfume transportation pressure, fall collision or user vigorously use. Perfume pump pump core column or nozzle parts due to structural precision, often can not withstand too much external force, once broken can not be repaired.

Performance:

- Pump head parts off, visible to the naked eye “fracture point”;

- The mouth of the bottle is exposed or can only see the pump core structure;

- Perfume nozzle directly loose down.

6️⃣ Negative pressure buildup in the pump (airtightness issues)

Detailed explanation:

In some perfume bottles with extremely tight seals (especially glass bottles that use a gland pump), after the pump cartridge extracts the liquid, a negative pressure is created inside the bottle, which in turn prevents the flow of liquid for the next press. This type of problem often occurs when there is not much perfume left or after a long period of non-use.

Performance:

- After spraying once, the next press is very strenuous or cannot be sprayed;

- It recovers briefly when the cap is opened and recapped;

- As the liquid diminishes, the problem becomes more pronounced.

Fragrance Pump Damage Causes Checklist

Below is the [Fragrance Pump Damage Causes Checklist] to help you quickly diagnose the root cause of problems such as perfume pumps that can’t be sprayed, broken, leaking, and so on. Applicable to brand after-sales, customer service, OEM quality control and other scenarios.

| No. | Symptom | Possible Cause | Type | Repairable | Recommended Solution |

|---|---|---|---|---|---|

| 1 | No rebound, pump feels soft | Spring failure / pump core damage | Structural issue | ❌ No | Replace pump (screw type) or whole bottle (crimp) |

| 2 | Resistance when pressing but no spray | Blocked pump core, disconnected dip tube, unprimed | Functional issue | ✅ Yes | Prime the pump; try upside-down spraying; check tube |

| 3 | Spray is uneven or drips | Nozzle clogged / dried fragrance residue | Functional issue | ✅ Yes | Clean with alcohol, warm compress, repeated pressing |

| 4 | Pump head is broken, detached, or loose | Impact damage / fatigue / mismatched thread | Structural issue | ❌ No | Replace pump (screw) or contact supplier (crimp) |

| 5 | Sprays once, then stops | Bottle vacuum / internal negative pressure | Usage issue | ✅ Yes | Remove cap to release air; avoid fully sealed storage |

| 6 | Liquid not being pumped | Tube too short, misaligned or disconnected | Structural/setup | ✅ Yes | Adjust angle or replace tube |

| 7 | Incompatible pump-bottle fit | Thread mismatch / incorrect crimp size | Installation error | ❌ No | Use matching standard size pump (e.g., FEA15) |

| 8 | Doesn’t spray on first use | New pump not primed (empty internal chamber) | Normal behavior | ✅ Yes | Press 5–10 times continuously to activate |

✅ Suggestions for use:

- For screw pumps: most replaceable pump head, suction tube and nozzle parts;

- For the gland pump (Crimp): usually can not be disassembled for repair, if damaged it is recommended to contact the supplier or replace the whole bottle;

- It is recommended that perfume pumps check the position of the suction tube before use, and avoid using and storing in hot or sunny environments

How can I avoid damage to my perfume pump?

Although the pump is small, it is the core of the perfume experience. Good habits + quality accessories + proper storage are the 3 secrets to prolonging the life of your pump and preventing damage.

- Correct use of the pump head: press gently, avoid excessive force

- Always “pre-press to activate” when using for the first time.

- Store properly, avoid high temperature, pressure and dropping.

- Clean the nozzle regularly to prevent clogging

- Choose a quality brand or qualified pump head supplier

- Avoid replacing pump heads with mismatched ones

Wholesale High Quality Perfume Pumps from Factory

If you are looking for high quality perfume pump sprayer with competitive price, BosTech Packaging, as a leading perfume packaging manufacturer in China, is your ideal partner. We specialize in the wholesale supply of high-precision perfume pumps, including Crimp and Screw sizes, which are fully adapted to international standard bottle tops such as FEA15, ensuring fine mist dispensing, strong sealing, and smooth pressing sensation, and are widely used by global perfume brands, cosmetic companies, and OEM customers.

BosTech has advanced injection molding equipment and automated assembly lines on the production side, which support fast delivery, personalization and small batch sampling to meet different stages of customers’ product development and market demand. We not only focus on quality control, but also provide one-stop service, from the pump head to the bottle, cap, plating collar full range of matching, really help brands to create a complete, advanced image of the fragrance products. Choose BosTech, choose the power of reliable fragrance pump factory direct supply.

How to Fix a Broken Perfume Pump?

How to Fix a Broken

Top 10 Crimp Neck Pump Sprayer Manufacturers in the World

Top 10 Crimp Neck Pu

Why Won’t My Perfume Pump Spray?

Why Won’t My P

What is a Perfume Crimp Pump and Why Use It?

what is a perfume cr